How complex is your global supply chain? If you have multiple sources shipping from multiple ports and various destinations, you probably need a control tower concept of some type.

Of course, you can just funnel all of your business through one big forwarder but there is a great price you pay for that. And you are placing a lot of trust in the giant forwarder that they are really proactively looking after your shipments.

Either create your own control tower or secure a neutral provider who specializes in this type of work. Neutral meaning not a competitor to your forwarders or carriers or other providers.

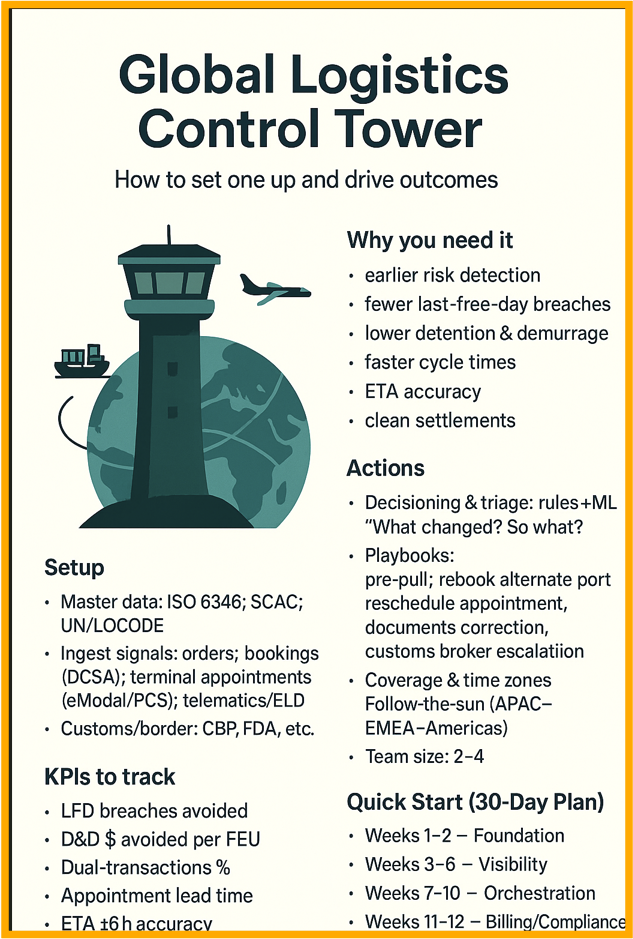

Control Tower benefits are clear: earlier risk detection, faster cycle times, fewer last‑free‑day breaches, lower detention and demurrage, more accurate ETAs, and cleaner freight settlements. Unlike a dashboard, it is accountable for outcomes and escalations.

How to set it up control tower. Build on your BI (Business Intelligence) tools or hire one. Tie in master data like container numbers, carrier SCAC codes, and UN location codes for ports/airports. The system ingests these signals from orders, bookings, terminal appointments, carrier milestones, telematics, and customs systems.

Then add decisioning: rules with machine score the risks and create the triggers to actions. Make a triage workspace that answers three questions: What changed? So what? Now what?

Staff the tower with a few expert logisticians, “rangers” who track the alerts and decide on actions to take. Tie this all up with AI improvements and your team only needs couple of people. Likely people with other responsibilities, that the “system” is alerting them to critical issues in addition to their other responsibilities.

Time zone and coverage.

Best if you can use a follow‑the‑sun model (APAC → EMEA → Americas) or as I had to develop with more limited operation, 12-hour coverage with an on-call element on opposite sides of the globe can work. We had a Malaysia team and US team with “on-call” coverage after hours.

Align monitors for key issues like port cut‑offs, last‑free‑day, terminal appointment releases, and even country holidays.

I love the forest watchtower analogy.

They continuously scan the “global horizon for “smoke”: weather, strikes, capacity crunches, misrouted cargo, and equipment shortages and even regulatory events like FDA holds, CBP exams, denied‑party issues data mismatches. When risk crosses a set threshold, the tower dispatches “firefighters” to: pre‑pull a box to stop storage, rebook a sailing, route to an alternate port, change appointments, document correction, or escalate as needed. The tower also responds when emergencies are called in.

Done well, the control‑tower becomes a profit-lever, not overhead: fewer expedites, lower accessorials, faster cash application, and a calmer operation. Identify delays sooner, fix what you can, change future order plans as needed, cut Per Diem charges, ETA accuracy, and stakeholder satisfaction, and keep improving your playbook. These are some ways control‑towers impact your outcomes.

Check out WOWL for ITMS offerings and even Control Towers!