Ocean and air impose hard limits. You can’t speed up the vessel, and mid-voyage “change of destination” COD orders often fail. These are some of the reasons “visibility” gets oversold. What can you do with the information you are getting?

But all is not lost. Knowing transit issues and following actual transit time metrics are needed to adjust the future plans. The planning for the next Purchase Orders is being processed and coordinating the ATP, Available-to-Promise, being made to customers on the other side of the globe.

Here are a few ideas on how to use visibility data-

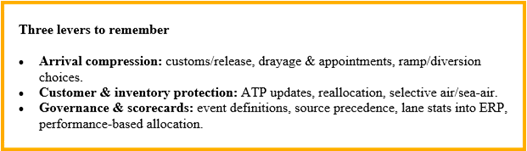

When delay hits, compress the arrival:

Pre-clear entries. Ensure “telex”/email Bill of Lading release to you carrier. Lock in dray, chassis, and terminal and ramp appointments. Use smart diversions like a cross-dock to truck where they pay off.

Protect customers and inventory:

Reallocate stock, update ATP and your promise dates, and consider using selective sea-air or spot-air routings for your products not yet shipped and sailed.

Tighten handoffs:

Arrivals to port or rail ramps, do what you can to speed up clearances and the drayage pickups and deliveries. You can make up a few lost days on the water this way. Consider using transloading at port to replace rail intermodal on those long land distances.

Change of Destination (COD):

While in transit on the water or in the air, including those transits ports and airports, CODs are very hard to execute successfully and end up callusing even longer delays.

Consider the risk and cost before trying to speed up shipments between the origin port/airport and the destination port/airport.

For next time, govern the data and measure what matters

Treat visibility feeds as raw data, unclean. Many sources will conflict on the same element; events will be wrong. Build a governance layer that defines events, ranks sources by precedence, and flags anomalies.

Harvest lane reliability scores, node dwell, supplier compliance, exception MTTR (Mean-Time-To-Resolution), and dollars avoided (expedites, D&D). Push these stats into your ERP/APS so the ATPs, the order releases/production calendars reflect new realities.

Use scorecards with teeth and use them to keep adjusting.

Bottom line: Visibility is vital—for monitoring goods in motion and capturing the data that powers accurate ATP and disciplined order timing. But it has limits. Pair it with governance and repeatable playbooks, and you’ll turn a live map into dependable outcomes.

WOWL has great visibility tools. WOWL has the Business Intelligence tools for you and the expert team of real people supported with real time AI. Check it out.