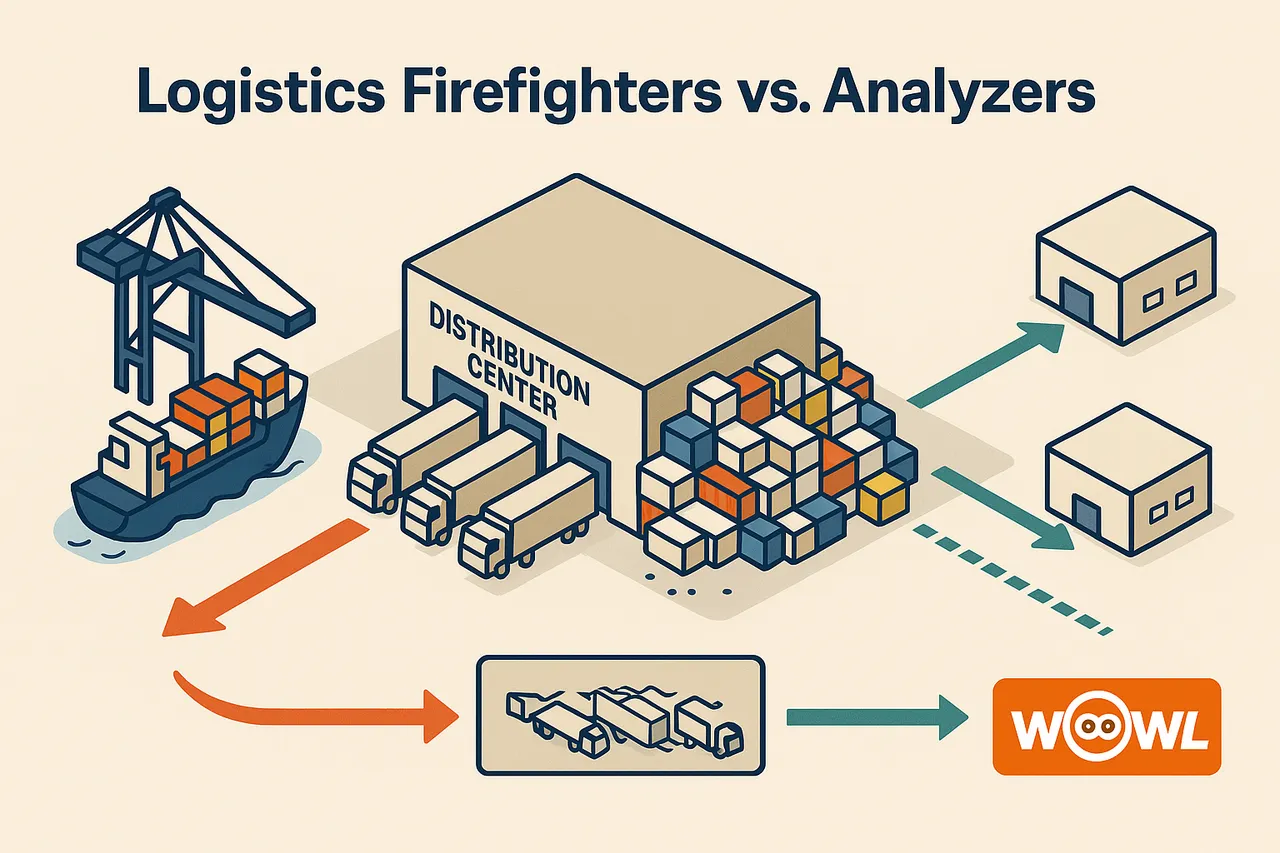

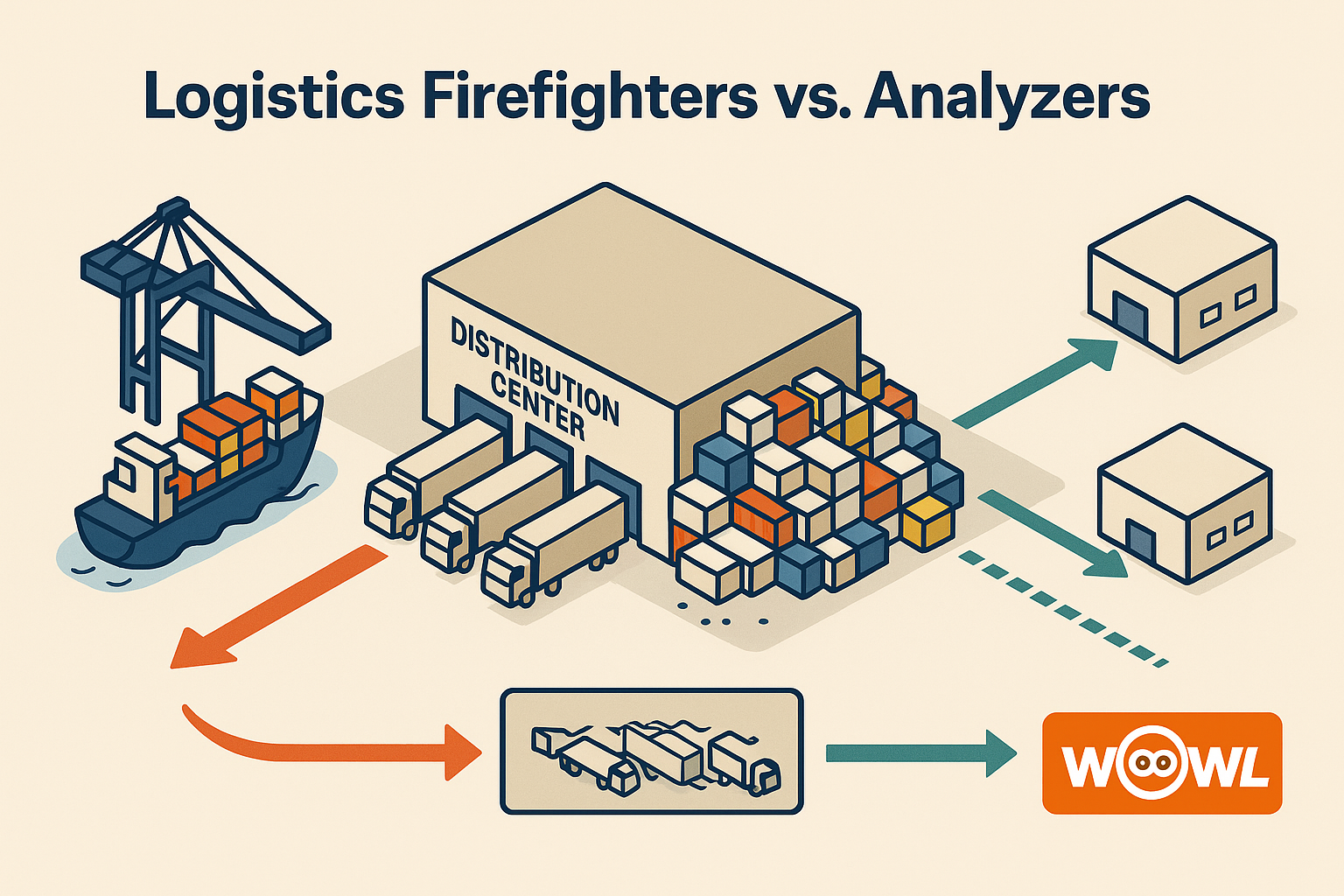

Two Speeds, One Supply Chain — The DC Pull Around.

The distribution yard in South Carolina looked like a storm surge that wouldn’t recede. All of a sudden there were 50 full ocean containers yet to be unloaded, then 75, then 100. Eventually more than 150 were parked in rows like unanswered questions. The DC was bursting after a warehouse closure forced a consolidation. To boot, COVID hit a month earlier; staffing was in flux; demand for our protective clothing (PPE) was surging.

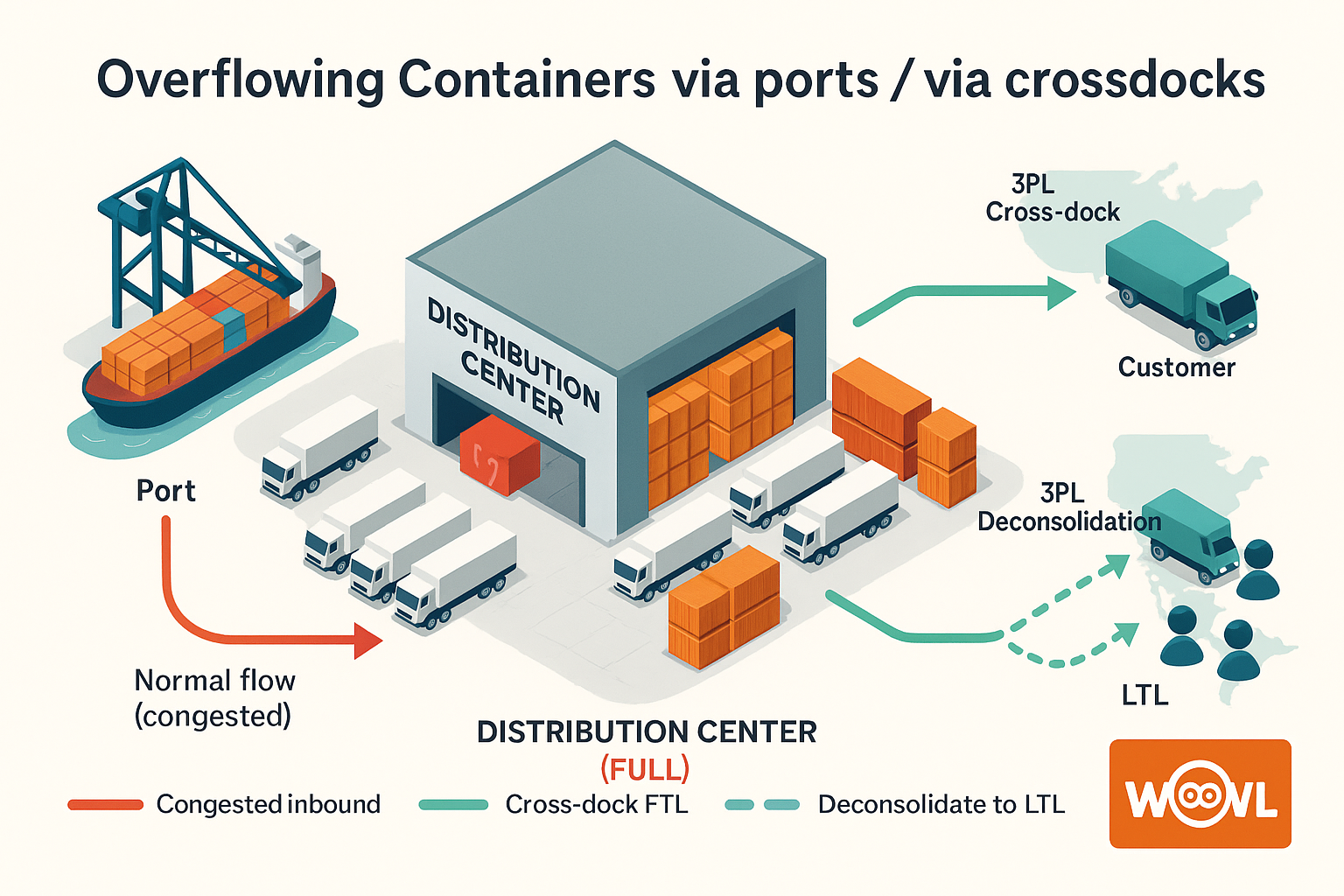

Stacy didn’t wait for a meeting. She owned imports, and she was a firefighter by reflex. While others froze, she started dialing. “Can you take a box today?” No contracts, no SLAs—just clear needs, firm prices, and trucks moving. As capacity at our partners ran out, she found new 3PLs, then new-new 3PLs. Our Sales pitched a bold idea: crossdock the arriving containers and sell them as full truckloads to any customer who could take them straight. Stacy made it real by noon. Containers moved. Yard rows thinned. It wasn’t pretty and it wasn’t standard, but it worked. Product started flowing.

Sam led domestic transport. He was an analyzer. While the yard burned hot, he was mapping failure points. The DC floor couldn’t breathe, so he planned bypasses. He methodically reconfigured racking, WMS hooks, and pick/pack lines—to receive full containers and cross them into LTL shipments for customers who wouldn’t take full loads. He negotiated slots, wrote SOPs, and put a cadence on the chaos. It took longer to fire up, but his plan caught on and escalated quickly.

For six months, the rhythm held: Stacy’s sprints cleared the choke points; Sam’s system kept them from reforming. She pushed product around obstacles in hours. He redesigned the route so tomorrow’s freight wouldn’t hit the same wall. Some days, her fast moves created new tangles—counts to reconcile, carriers to soothe. Some days, his caution would have missed a cutoff if not for her quick reroute. Together, they were the metronome the DC needed: stabilize now, correct fully.

By summer’s end, the yard was back within its lines. The DC flowing, orders were moving, customers were supplied, and the outside network Sam built became a standing option in the playbook anytime volumes spiked. And Stacy’s “call-now” map is the emergency contact tree for future surges.

The lesson: you need both speeds: firefighters and analyzers. The work is to choreograph the handoff—give the firefighter the first ninety minutes and the analyzer the next nine hours. In South Carolina, that dance kept promises when missing wasn’t an option.

It would have been better to have WOWL around back then. It would have made our planning, inbound visibility and product details in container much clearer, faster, cleaner. Better, cleaner data and an actual team to back us up and provide us with advice and contacts. It would have sped up our process so much better!

AndyG@WOWL.io