When I took the new role, the bigger title, the bigger scope, the bigger mess, the welcome gift was a mandate with no cushion: “Fix global logistics, get it under control, improve service, and lower the cost.

Make it faster, cheaper, smoother, and more reliable. BUT headcount is frozen.” They didn’t hire me in spite of the chaos; they hired me because of it. Still, the first weeks felt like a stress test. My inbox throbbed, budgets were already stretched, and I was handed one slot to hire domestics support while I “figured out” everything else: ten thousand international shipments spanning Asia, North America, Europe, APAC, and the Middle East.

In my first quarterly review, the CFO lobbed the question I’ve heard my whole career: “Why don’t we just let the big forwarder handle everything?” I knew that tune. When the dog becomes the watchdog too, the scorecard bends toward assets, not outcomes. We didn’t need more trucks or prettier dashboards. IF I couldn’t build an internal team, we needed a neutral control—someone to own the seams between eleven carriers, three forwarders, two brokers, parcel, drayage, and our plants. Because if no one owns the handoffs, cost and chaos leak right through them.

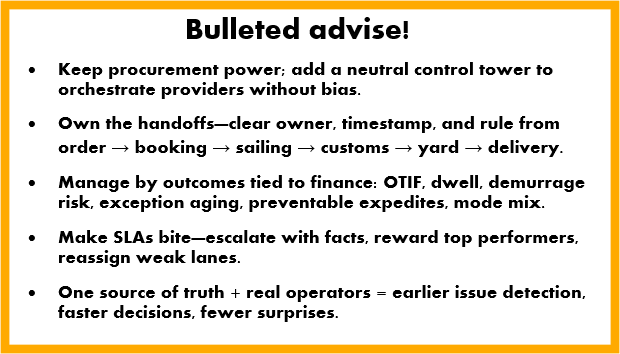

So I went to market with a clear line: I would keep procurement power—my carriers, my contracts, my lanes and I would add a control tower whose only product is oversight. Day one with our chosen partner, we mapped the network we actually run, not the tidy slide version: orders to bookings, bookings to sailings, sailings to customs, customs to yard, yard to delivery—each step with an owner, a timestamp, a rule. I hired a sharp domestic lead; I took the globe.

The first test arrived like a siren: a recall that doubled outbound orders and yanked forward inbound safety stock. We didn’t argue mode; we argued outcomes. Sailings were retimed. High-risk SKUs were pre-cleared. Drayage was staged to revised ETAs. When a carrier tried to shave free time, we escalated with facts and teeth. Before customers asked, service had answers. Sales had credible ETAs. Planning re-sequenced builds without panic. Good partners got cleaner tenders; weak ones improved or ceded lanes. And for the first time, we had one truth: dwell, demurrage risk, on-time, exception aging, preventable expedites.

By quarter’s end, finance saw the story their way: fewer expedites, avoided demurrage, steadier OTIF, smarter mode mix—net savings even after fees, with better service. Leadership kept strategy and relationships. Our tower kept the clock, the scorecard, and the heat on every handoff.

That’s why I was hired. Not to outsource judgment, but to install it. To keep control and make the whole machine visible, accountable, and faster. In this bigger job, the budget squeeze didn’t define us, the discipline did. We chose to watch, measure, and lead. That’s how you serve customers, hit the number, and justify the promotion that brought me here.

Our job in logistics & supply chain management is to get the job done. We use what we can to be effective and successful. Nowadays that means using inside teams mixed with outside teams. It means solid professional help made from strong relationships and building on improving technologies.

WOWL is a support for all global logistics making supply chains work.